| TRUNG KIEN JSC is one of the leading packaging companies in Vietnam. Our company specializes in manufacturing and trading all kinds of plastic packaging: |  |

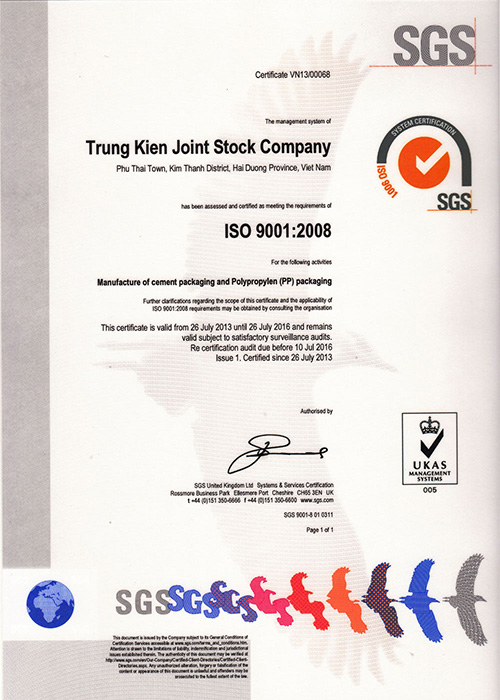

ISO 9001:2008 Certification

ISO 9001 is the international standard for quality management systems issued by the International Organization for Standardization (ISO), which can be applied in all fields of production, business & service.

So until now it considered one of the most basic solutions, the first platform to improve the capacity of the enterprise management. Therefore, most enterprises, when they want to reform their apparatus, improve their competitiveness, choose to apply ISO 9001: 2008 to their business. Then adopt more advanced systems such as TQM (Lean production), Lean production (Lean production), 6 sigma (philosophy of improvement based on 6 sigma principle), etc.

The enterprises who wish to apply ISO 9001: 2008 should read the following two ISO 9000: 2008 standards:

- ISO 9000: 2005 (Vietnam equivalent standard: TCVN ISO 9000: 2007) to understand the meaning of terms used in ISO 9001: 2008. The name of ISO 9000: 2005 is "Basis and vocabulary of quality management system".

- ISO 9001: 2008 (Vietnam equivalent standard: TCVN ISO 9001: 2008) to know what requirements the management system of your business needs to meet.

In addition, in order to enhance the effectiveness of the quality management system, enterprises can study and apply them according to the guidelines of ISO 9004: 2009 (Managing for the sustained success of an organization - A quality management approach).

The purpose of ISO 9001: 2008:

The ISO 9001: 2008 standard specifies the requirements for an organization's quality management system:

- It is necessary to demonstrate the ability to provide a stable product that meets customer requirements as well as regulatory requirements related to the product.

- Want to improve customer satisfaction through the application of quality management system in accordance with ISO 9001: 2008. Maintaining involves continual improvement of the system to ensure compliance with customer requirements, regulatory requirements related to the product.

8 quality management principles.

ISO 9001 is a standard formed by the accumulation of practical experience from the many successes and failures of many companies around the world. Throughout the study, ISO experts have identified eight quality management principles that should be considered as the foundation for building a quality management system:

Principle 1: Customer orientation.

Principle 2: Responsibility of Leaders.

Principle 3: Participation of people.

Principle 4: Process Approach.

Principle 5: Systematic approach.

Principle 6: Constant Improvement.

Principle 7: Decision based on facts.

Principle 8: The cooperation of mutual benefit with suppliers

These eight principles of quality management are set out in ISO 9000: 2005 (TCVN 9000: 2007) to help business leaders master the spirit of ISO 9001: 2008 and use it to lead the business. The higher results when applying ISO 9001: 2008 to your business.

Quality management philosophy

1. Quality system determines the quality of products and product creation is a process of linking all parts, is the process of turning the input into output to the consumer, not only the Technical details of the production side but also the effectiveness of other departments such as administration, human resources, finance.

2. Do right from the beginning is the most quality, most economical. Precautionary focus from the beginning ensures to minimize unnecessary errors, save time, human resources ... There are activities adjusted during the operation, the end of this process is the input of The other process.

3. Doing the right thing from the beginning is the best prevention. As mentioned above, each member has different jobs that form a chain link together, the output of which is the input of the other.

4. Process management and decision-making based on facts, data. Desired outcomes will be achieved effectively when resources and related activities are managed as a process. All valid decisions are based on the analysis of data and information.

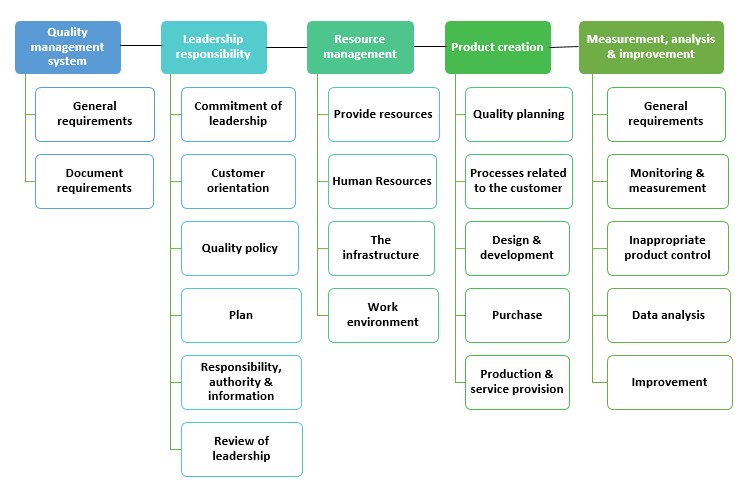

Content of ISO 9001: 2008 standard:

Terms 0: Introduction.

Terms 1. Scope of application.

Terms 2. References.

Terms 3: Terms and definitions.

Terms 4: General requirements for quality management systems.

Terms 5: Responsibility for leadership.

Terms 6: Resource Management.

Terms 7: Product Creation.

Terms 8: Measurement, analysis & improvement.

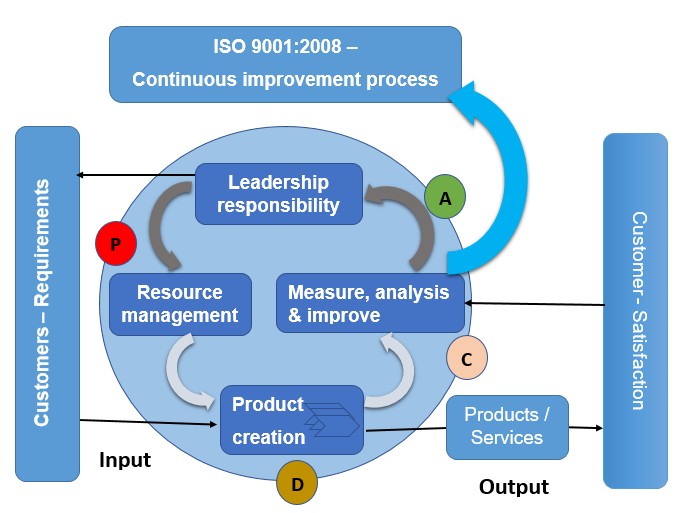

Model terms of ISO 9001: 2008 system

As required by ISO 9001: 2008 standards, enterprises must issue and apply at least the following documents:

1. Quality policy.

2. Quality objectives of the company and quality objectives of each functional department level.

3. Quality manual.

4. Six (06) basic procedures:

- Procedure (process) control of the document

- Procedure (process) control of records

- Procedures (processes) for internal evaluation

- The procedure (process) of inappropriate product control

- Procedures (procedures) for corrective action.

- Procedures (procedures) for preventive action.

It is often possible to incorporate etching and preventive action into a procedure that is corrective and preventive action procedures.

In addition, in order to demonstrate that the enterprise has applied and maintained the application of ISO 9001: 2008, an enterprise shall establish and maintain at least the following records in order to provide certification bodies ISO 9001: 2008. (Read the article "ISO 9001: 2008 - list of documents, minimum quality records" for more details)

In addition to the required procedures required by the ISO 9001: 2008 standard, an enterprise can develop additional procedures, work instructions, and make the necessary records to ensure the effective management system.

In short: The ISO 9001: 2008 quality management system can not guarantee that processes and products are not defective. But make sure this system creates the strength and credibility of the organization. On:

- Obtain clear policies and quality objectives, with the highest level of management attention through periodic review of the entire system.

- Build up an appropriate organizational structure and resource allocation to perform each task that increases the likelihood of achieving the desired requirement

- Clear and consistent work processes, ensuring every job is done appropriately and scientifically.

- A system where there is always feedback, improvements to make errors and errors in all parts less and less to repeat errors and mistakes with the old cause. Out

- A mechanism for periodic reviews to continuously improve the entire system.

- Build a process that ensures all customer requirements are assured before accepting customer requests.

Author: Trung Kien

Reader Comments

- Online43

- Search engine3

- Guest40

- Today13,645

- This month159,319

- Total11,515,146