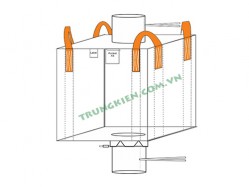

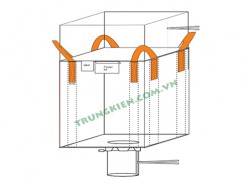

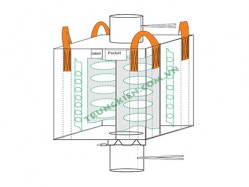

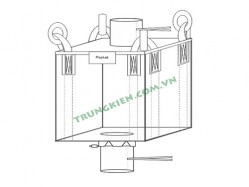

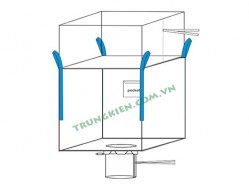

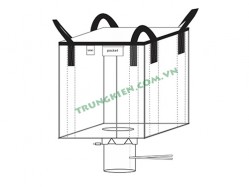

FIBC bulk bags production flow

We have invested in modern plant equipment using vertical integration, along with factory standards to produce large quantities of jumbo bags (FIBCs).

Our production line is vertically integrated and operating in a cloded process. Each production stage is quality tested with state-of-the-art machinery and equipment made in the United States and the United Kingdom. Investing in a vertical integrated production line helps us get rid of dependency on our suppliers to ensure that the quality control of our products meets the highest standards for the entire product line. And ensure that orders are delivered on time.

Production Flow of FIBC bulk bags:

1. Mixing materials (plastic beads & color beads).

2. Yarn extruding.

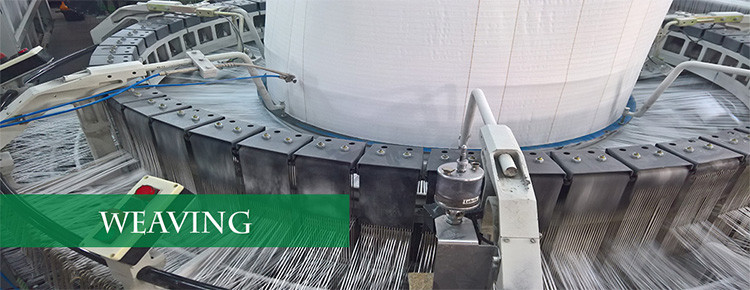

3. Weaving fabric & belt.

4. Coating & laminating (if required).

5. Heat cutting.

6. Printing (if required).

7. Sewing.

8. Quality control.

9. Folding & Packing

10. Storing.

Production Flow of FIBC bulk bags:

1. Mixing materials (plastic beads & color beads).

2. Yarn extruding.

3. Weaving fabric & belt.

4. Coating & laminating (if required).

5. Heat cutting.

6. Printing (if required).

7. Sewing.

8. Quality control.

9. Folding & Packing

10. Storing.

Author: Trung Kien

Reader Comments

You must login to comment this article

Older articles

CUSTOMER SUPPORT

STATISTICS

- Online15

- Search engine2

- Guest13

- Today450

- This month90,247

- Total11,446,074

PRODUCT CATEGORIES

MANAGEMENT SYSTEMS

QUICK VIEW PRODUCTS